CONTACT US

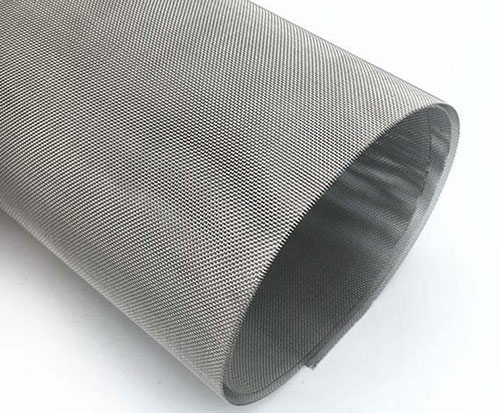

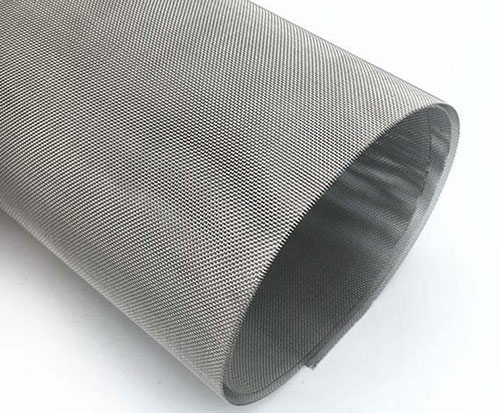

Product Quick Details:

● Place of Origin: China, Anping

● Brand: TianHao

● Certification: ISO9001

● MOQ: 1 PCS/Sqm

● Packaging Details: folded and packed in wooden pallet

● Delivery Time: stocked items: within 3 works days;

● Customized items: 7-20 days

● Payment terms: T/T, PAYPAL, Western Union, Trade Assurance

● Supply Ability: 10000 units/sqm per week

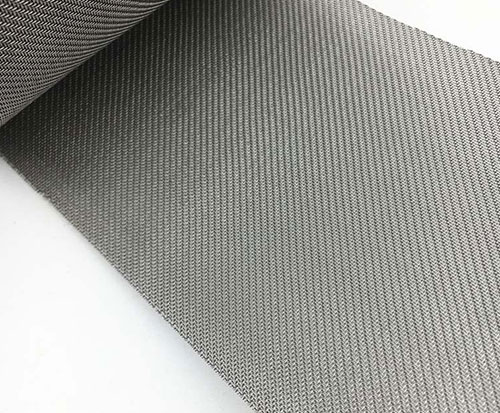

Features:

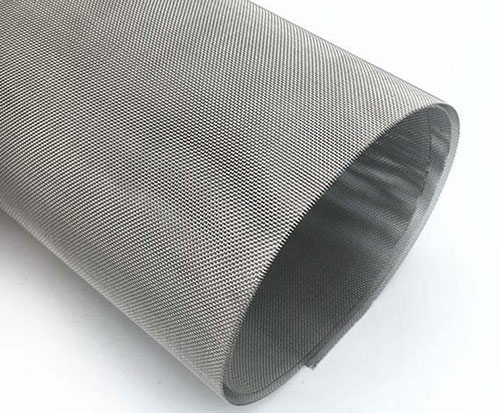

1. Extremely robust material with electric heat shielding properties

2. Prevents attack in severe oxidizing, carburizing, sulfiding and nitriding media

3. Mesh Size: 0.2mesh/inch to 200mesh/inch

4. Wire dia: 0.05mm to 8.0mm

Grade:

● Incoloy 800

● Incoloy 800H & 800HT

● Incoloy 825

● Incoloy 840

UNS N08811

Incoloy 800 is a nickel – iron – chromium alloy with good strength and excellent resistance to oxidation and carburization in high temperature atmospheres up to 1100 degrees F. It also resists corrosion in many aqueous environments. The low carbon content helps prevent sensitization and consequent intergranular corrosion of weld heat-affected zones. Used for flue-gas scrubbers and for handling phosphoric and sulfuric acids.

USN N08810 & UNS N08811

The Incoloy 800H and 800HT nickel – iron – chromium alloys are the same basic alloys as Incoloy 800 but with significantly higher creep-rupture strength. This is achieved by close control of carbon, aluminum and titanium contents in conjunction with a high-temperature anneal. These alloys are used in chemical and petrochemical processing, in power plants, industrial furnaces and heat treating equipment.

UNS N08825

This is a nickel – iron – chromium alloy with additions of molybdenum and copper. It has excellent resistance to both reducing and oxidizing acids, to stress cracking, and to localized attack such as pitting and crevice corrosion. Incoloy 825 is especially resistant to sulfuric and phosphoric acids. Often used in chemical processing, pollution-control equipment, oil and gas well piping, nuclear processing, acid production and pickling equipment.